Production

Production / Preparation

Countless and hard working 6-axis robots keep the production flow running 24/7 by opening holes and cutting lengths for different models obtained from the same molds which create great opportunity to reduce investment costs for customers.

Production / Molding

CTP can mold up to 3000 x 2000 parts in a single shot with its highly

skilled personnel and technological machine park. Many high accuracy and parallel controlled presses work on best sequence supplemented by MRP, there is always free-capacity in CTP to seek for new markets and

opportunities such as ramp-up phases of its customers.

Preparation is: cutting, sanding and binding, which is a very important pre-phase where molded parts are becoming ready for top coat paint and final assembly.

Production / Tooling

In-house Tool Making Capability = cheaper investment + shorter lead times + better reactivity on modifications + single face to the customers from day 1 till the end of SOP for customer based projects.

Many high-speed and wide tabled CNC‘s produce 100% of tools that are running at CTP facilities since decades.

Being assisted by R/M Production and tool making, molding is the core business of CTP carried out with high-level know-how and experience since 1989.

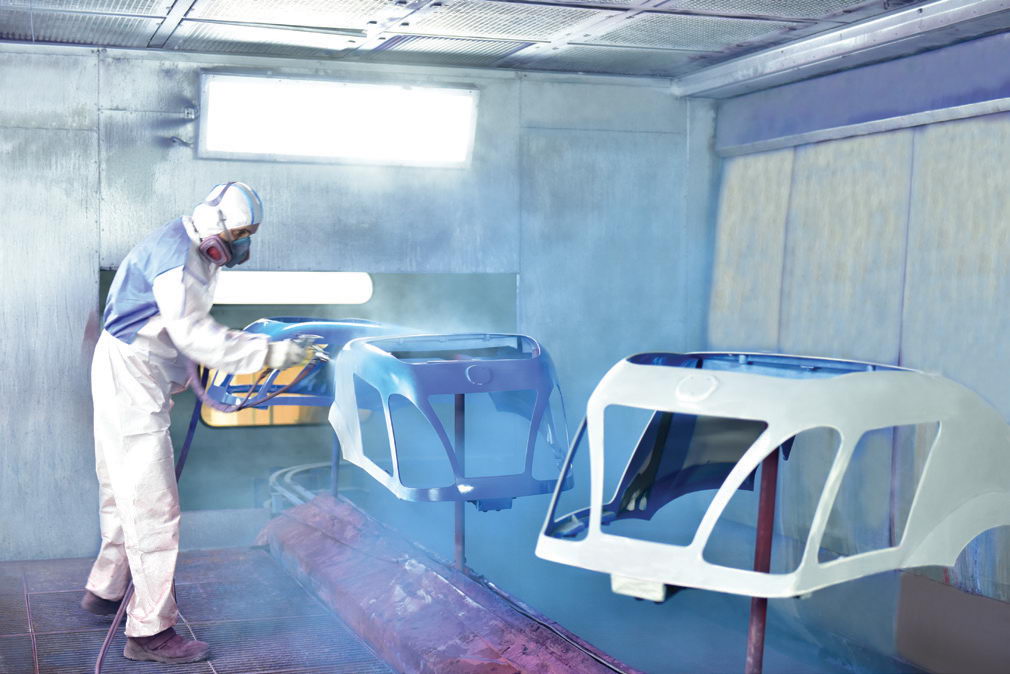

Production / Painting

Just In Time & Just In Sequence can only be achieved by having many fully automated and power & free rotational conveyor systems combined with high oven capacities.

Primary and top coating are offered to CTP customers in standard, in CTP paint-shops located at 3 different locations; Istanbul, Adapazarı and Ankara; where our parts transform to faces of worldwide known brands.

Production / Final Assembly

Material enters to final assembly as parts and leaves as products. CTP offers products fully assembled to its customers. Mounting and glueing grids, logos, metal hinges, insulations, headlights, cables and many other components can all be procured and managed by CTP purchasing software.

Best price vs performance can only be achieved by assembling as many components as possible to the hoods, fenders, dashboards, roofs, spoilers, bumpers, side extenders and step covers that CTP produces.